The HOST 50 CNC system is a bus-type fully digital CNC device that supports the EtherCAT bus protocol. It features technologies such as multi-axis and multi-channel control, high speed and high precision, composite machining processes, and multi-axis group synchronous control. The system adopts acceleration/deceleration control algorithms, small-line-segment machining control algorithms, and cubic spline interpolation algorithms, which can meet the control requirements of high speed and high precision. This product can be applied in industries such as aerospace, automobile manufacturing, energy and power, hardware molds, and 3C, providing efficient and accurate motion control and process solutions for various industries.

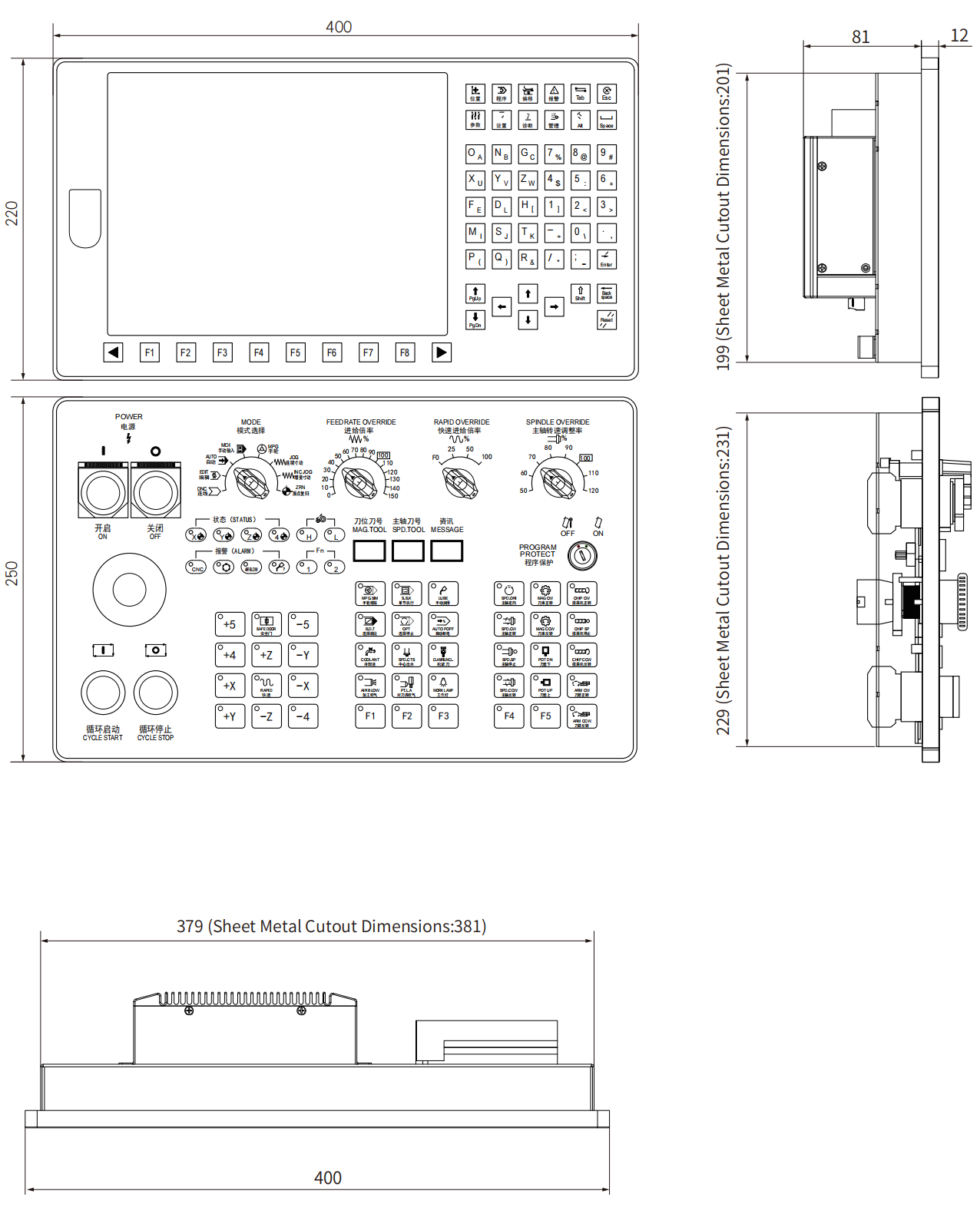

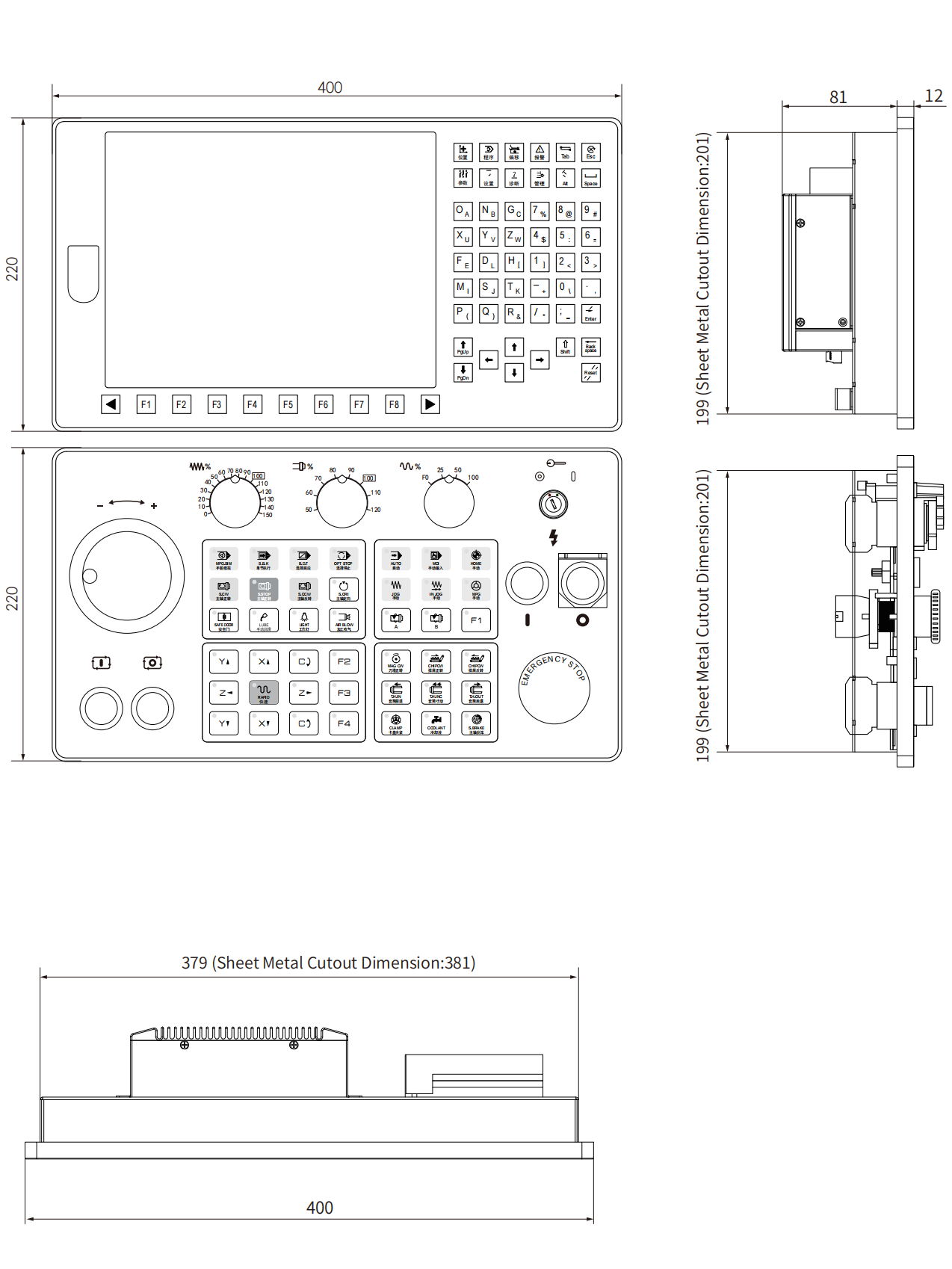

Installation Dimensions

Turning-Milling System Installation Dimensions

Milling Machine System Installation Dimensions